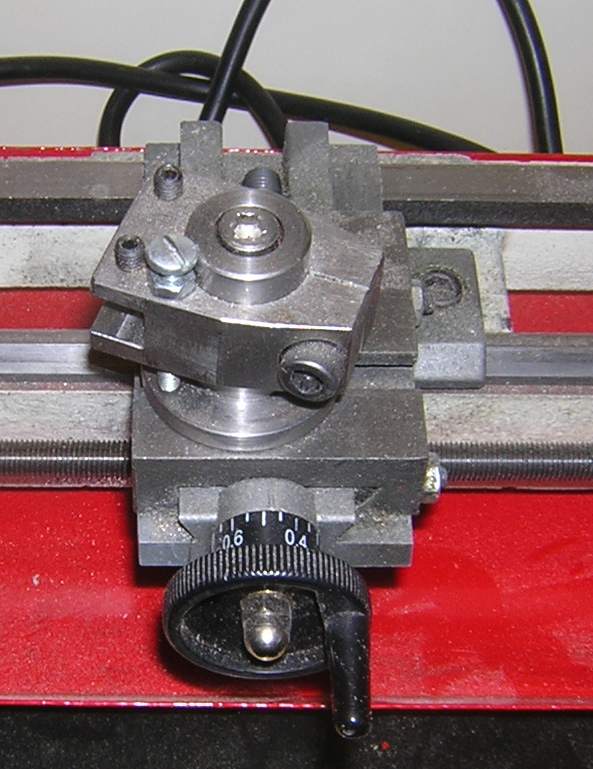

Following a search-around I found a simple enough type to make in my them limited workshop. It is based on the "Norman Patent" type design which is built from a rigid post on the cross slide and the tool holders are secured to the post using a clamp screw.

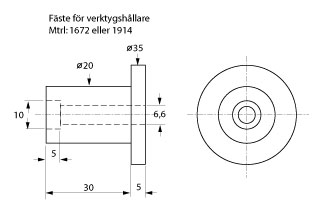

This solution was sketched up and I found a way that would work for me. I also had some readily suitable material. First out was the toolpost then the holders. The post was designed as below.

As can be seen The post have a foot wider than the post itself to provide a better stability. I also added a small "button" that is fitted under the foot and into the T-slot to prevent the post from rotating under load. The height was made a bit higher that the existing toolpost to be sure that any foreseeable type of holder can be accomodated.

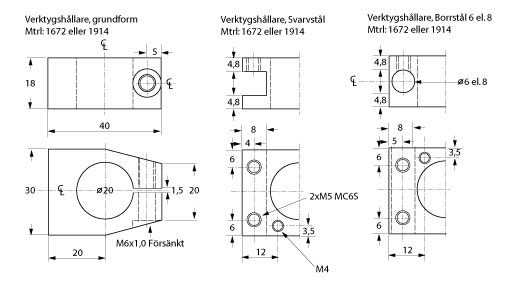

Time for the tool holders. I made them as small yet simple as possible to make. The idea was to make a larger number of holders to fit different tools. The total number turns out to be quite big, see below.

- Ordinary straight holders - ~10 pcs

- Boring tool holders - 3 pcs

- Knurling tool holders - 2 pcs

- DTI holder - 1 pcs

- Ball truning holder - 1 pcs

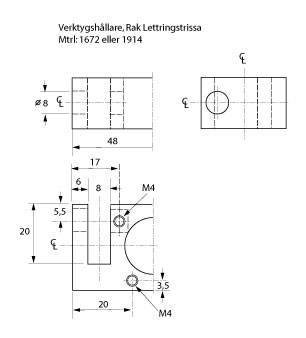

This makes for close to 20 holders just to cover the basic need! A bit to do. The basic shape looks as below. The basic block and the measures for straight and boring tools.

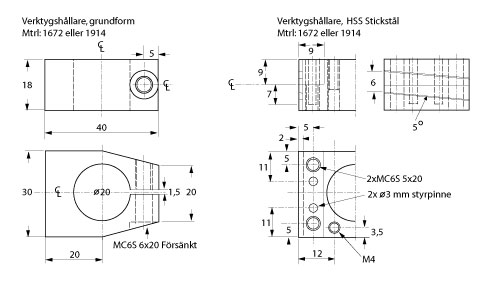

I quickly made a few while waiting for the proper material to arrive. I use standard BMS here. The type below is for the thin (1.5 mm) blade parting tool holder.

Then I had a piece perfect for making a straight knurling tool holder.

Generally, the Norman Patent type tool holder is very good for batch jobs.

- Cut the appropriate number

- File/turn to measure

- Put the central hole in position

- Drill and thread the set screw hole

- Drill and thread the tool holder screw holes

- Slit the holder so it can be clamped to the toolpost

- Drill/Mill/Turn the tool slot.

No complicated jobs at all but gives good preactice. It all turned out well and now I have a good set of tool holders and the QCTP system works beautifully.